The integration of humanoid robots in the production process of electric vehicles by Chinese company Nio is revolutionizing efficiency and quality standards. This article explores the significant advancements and collaborations in this innovative initiative. Discover how Nio is at the forefront of integrating humanoid robots in electric vehicle production, leading the way towards enhanced efficiency, quality, and safety standards in the automotive industry. Join us as we delve into the future implications and benefits of implementing Humanoid Robots in Electric Vehicle Production.

Benefits of Using Humanoid Robots in Electric Vehicle Production

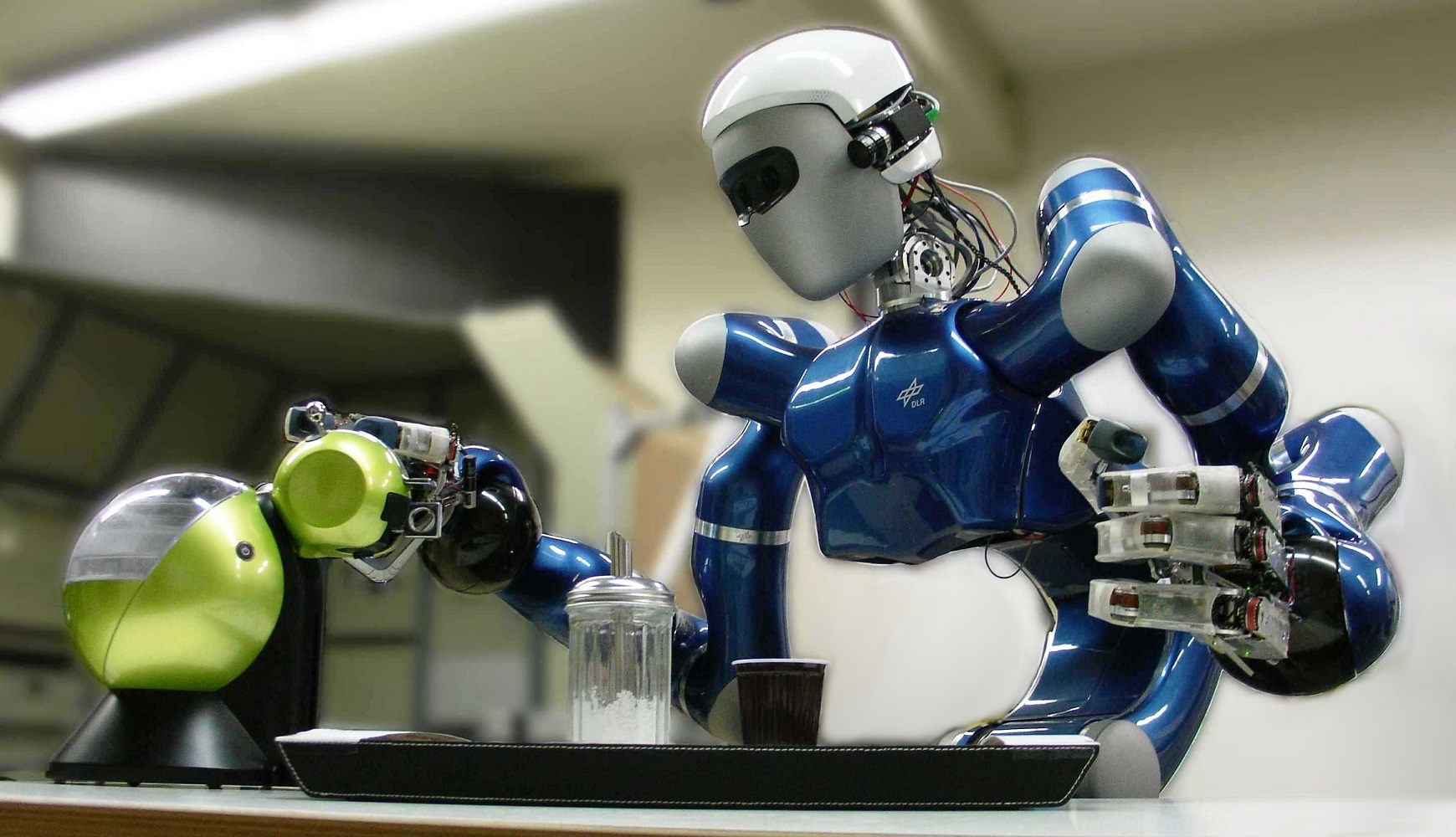

Introducing humanoid robots in electric vehicle production, as demonstrated by Nio’s endeavors, presents a paradigm shift in manufacturing. With the Kuavo humanoid robot developed by Leju Robotics and powered by HarmonyOS, production processes stand to witness exponential enhancement in efficiency through seamless integration capabilities. This technology promises to tackle intricate tasks within industrial settings, propelling the sector towards heightened productivity levels.

Moreover, the incorporation of humanoid robots like the Walker S from UBTech Robotics for quality control tasks signifies a meticulous approach towards ensuring impeccable standards in electric vehicle assembly. Nio’s strategic formation of a humanoid robot team, leveraging cutting-edge technologies such as 5G and vision algorithms, holds the promise of revolutionizing manufacturing precision and speed. By prioritizing accuracy and efficiency, Nio sets a new benchmark for the industry’s operational excellence.

In alignment with the industry’s progressive trajectory, the synergy between Nio, Huawei, and Leju Robotics in exploring humanoid robot integration heralds a transformative era in electric vehicle production. As Nio drives forward with its commitment to testing the Kuavo robot and emphasizing HarmonyOS integration, the overarching goal remains crystal clear – to elevate the quality, efficiency, and safety standards within the electric vehicle manufacturing domain. This strategic shift not only denotes innovation but also lays the foundation for further advancements that can redefine the automotive landscape.

Future Implications and Collaborations

In the dynamic realm of Humanoid Robots in Electric Vehicle Production, adopting humanoid robots can revolutionize industry standards. With a focus on quality, efficiency, and safety, the integration of these robots promises a leap forward in innovation within the automotive sector. This advancement heralds a new era of precision and reliability in electric vehicle assembly processes.

Collaboration between industry giants like Nio, Huawei, and Leju Robotics signifies a strategic alliance for progress. By pooling resources and expertise, these key players are poised to drive substantial enhancements in sustainable manufacturing practices. This synergy not only ensures operational excellence but also paves the way for cutting-edge technological advancements in electric vehicle production, reshaping the future of industrial automation.